|

|

|

| Applications |

|

| • Rigid Bars |

|

| • EDM Electrodes |

|

| • Fuselage Mass Balancing |

|

| • Riveting Dollies and Bucking Bars |

|

| • Electrical Contacts for Switchgear |

|

| • Vibration Damping & Dynamic Balancing |

|

|

| The Technology of obtaining a microstructure of Tungsten grains homogenously embedded in a conductive matrix of high purity copper has been developed and perfected by TUNCOSI. |

|

|

| |

To fulfil critical demand of high resistance to arc erosion and good electrical conductivity. To fulfil critical demand of high resistance to arc erosion and good electrical conductivity. |

|

Suitable for spark erosion of hard materials like Cemented Carbide for maximum electrode life and minimum downtime. Suitable for spark erosion of hard materials like Cemented Carbide for maximum electrode life and minimum downtime. |

|

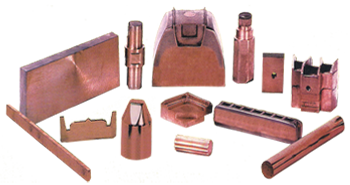

These alloys are manufactured specially to customers drawings and specifications. These alloys are manufactured specially to customers drawings and specifications. |

|

Having specific properties of high density and high modulus of elastictiy, they are superior in application such as rigid boring bars, counter balancing weights, etc. Having specific properties of high density and high modulus of elastictiy, they are superior in application such as rigid boring bars, counter balancing weights, etc. |

|

They are machinable by conventional metal removal techniques like turning, milling, drilling or grinding. They are machinable by conventional metal removal techniques like turning, milling, drilling or grinding. |

|

| |

| Standard Composition of Tungsten Copper Products |

| Grade |

Composition |

Density gm/cm3 |

Hardness HV30 |

Electrical Conductivity % IACS* |

T-60 |

W-60, Cu-40 |

13.0-13.7 |

130-175 |

40-50 |

T-70 |

W-70, Cu-30 |

13.8-14.6 |

150-210 |

38-45 |

T-75 |

W-75, Cu-25 |

14.6-15.0 |

180-230 |

35-42 |

T-80 |

W-80, Cu-20 |

14.8-15.6 |

210-270 |

30-38 |

| |

|

|

|

*100% IACS = 0.58001/OHM-CM |

|